Because the success of reconditioning is relative to the quality of repaired products: How is a real functional test carried out?

“Second hand” products are all the rage! And electronic products are not excluded from this trend.

The success of these reconditioned devices is inevitably related to the products’ quality and the trust clients put in them.

Since the end of the first lockdown, in spring 2020, the reconditioned market has seen an unprecedented growth, notably in terms of smartphone sales.

What tests are carried out on a smartphone before putting it back on the market?

Focus on the industrial process behind these “recycled” smartphones.

Reconditioned smartphones: a booming trend

According the “Union Fédérale des Consommateurs – Que Choisir”, a French consumer organisation, at the end of 2021, reconditioned smartphones represented 10 to 15% of smartphone sales and this number is constantly growing.

France 2 confirmed these numbers in a story on this topic, on the 1pm news, on Tuesday, January 4th, 2022. It highlights the importance of the quality of products put back on the market.

These second hand devices are sold at prices 30 to 50% lower than those of new products and therefore attract a new clientele with a smaller budget.

The latest report by Arcep announced a 25% increase in sales compared to 2019 and a market estimated at 700 million euros for 2020.

Apple’s iPhone 8 remains the biggest selling reconditioned smartphone in the same year.

*watch the news story (story begins at 00:18:19)

3 good reasons for buying a reconditioned smartphone

1. Reducing the environmental impact

According to a study by the “Agence de Transition Ecologie – ADEME”, choosing a reconditioned device “is the equivalent of preventing the extraction of 82kg of raw material and 25kg of greenhouse gas emissions”. Buying a reconditioned smartphone is therefore an eco-friendly choice.

2. More attractive prices.

The reconditioned market offers more accessible prices therefore allowing you to purchase a relatively recent smartphone without breaking the bank.

3. Reducing waste.

The device is used for longer, offering a more virtuous life cycle.

Reconditioning, how does it work?

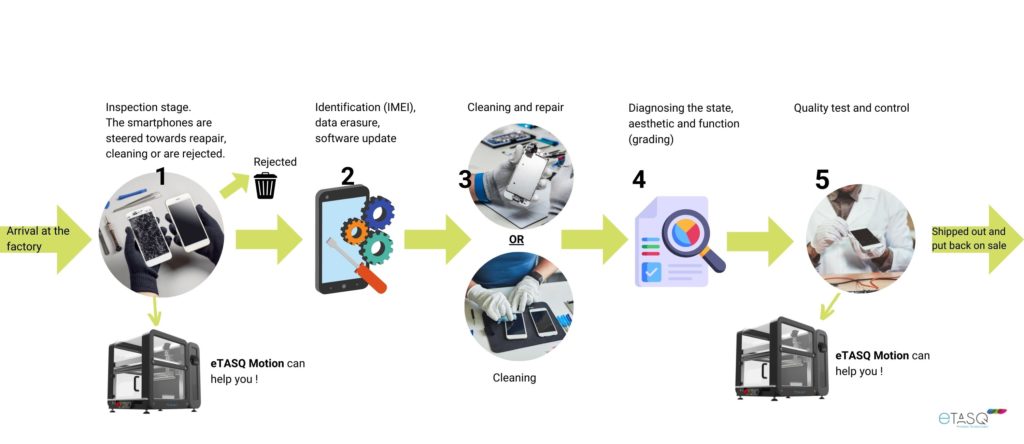

Companies that specialize in reconditioning smartphones, purchase devices in unknown conditions from resellers or operators. They all go through an inspection stage and will be guided through repair stages, cleaning stages or more towards rejecting the device completely.

Example of a smartphone reconditioning procedure.

Certain devices are therefore restored (repairing one or several components and, if necessary, changing the damaged parts).

Before leaving some repair centres, all smartphones are tested to ensure their correct functioning overall.

The more functional tests are therefore the key point before putting the product back on the market. They are often carried out manually which amounts to a lot of time and energy spent by the team of testers. However, these tests can be automated!

Test automation is therefore useful for both the initial inspection of smartphones as well as post-restoration control.

Functional testing: definition

A functional test consists of validating all of a product’s expected functionalities. Current products are often presented via their human machine interface.

In regards to smartphones, this test is mainly carried out via its screen.

A functional test combines a list of actions that must be carried out to ensure the device’s correct functioning overall.

Functional testing of smartphones

The process of functional testing of smartphones:

- Screen – Display:

- Monitoring the sharpness and display of colours

- No cracks, stains, light halos or dead pixels

- Screen – touch:

- Monitoring the touchscreen by scrolling over it

- 3D Touch / long tap

- Buttons:

- Testing the Home, Home, Lock, Volume+, Volume- and Mute (iPhone) buttons

- Loud-speakers:

- Confirming sound emission and validating non-saturation of loud-speakers

- Microphone:

- Emitting a sound captured by the microphones and analysing the recorded sound

- Connectivity:

- Testing connectivity of WiFi, 3G/4G/5G and Bluetooth chips

- Camera:

- Monitoring, for both optics (front and back), adjustment, sharpness, QR Code reading

- Monitoring the lack of stains on the optic and defective adjustment

- Flash:

- Making sure it turns on

- NFC:

- Monitoring tag reading

- Battery:

- Testing wire-charging capacity

- Testing induction-charging capacity

- SIM Card:

- Testing the possibility of contacting the operator

These functional tests are carried out in phase 1, i.e. the inspection phase upon arrival at the factory, the smartphone will go through the repair stages if necessary, then through cosmetic cleaning and grading, then in phase 5, the quality test and control phase, before being shipped out and put back on sale!

Why is the automation of functional testing important?

Automating functional testing allows companies to provide constant quality and cadence of execution. For smartphones, the volumes are significant, in the range of tens of thousands of units per month. It is therefore important to facilitate operators’ tasks.

Are you looking to be more in control of your testing procedures, getting rid of the human variable and having more confidence in your products’ quality? Then lean on automation!

You will improve your productivity as well as your profitability, and mobilise your teams where they will add more value.

The essentials for proper reconditioning

Thanks to a robot, programmed to test your products, you can automate your testing process.

The pre-requisites:

The machine must, just like a human, be capable of tapping on a screen (touch), analysing the display (sight) and hearing the different sounds (sound).

The tasks that the robot must be able of accomplishing are as follows:

- Changing smartphones and devices rapidly

- Providing a panel of tests on all expected functionalities

- Getting rid of the human variable

- Providing testing traceability

- Adapting to new product ranges

- Being resistant to production constraints

- Interfacing with ERPs

It must be equipped with the following assets:

- Simple to use, program and improve

- Easy to deploy

- Rapidly carries out tests

- Reliable (constant quality and cadence)

The goals of this collaboration:

- Allowing easy implementation within the R&D service or the testing process

- Mobilising the teams where they add value (and improve their skills)

A testing robot ensures constant quality, you will have even more confidence in your products.

The road to test automation with eTASQ Motion

Our one of a kind, patented solution, eTASQ Motion, is a revolution for manual testing.

This robot allows you to carry out tests end-to-end, in an automated fashion.

The strength of this solution is that it is modular and adaptable. Personalisation for your industrial activity is therefore totally doable.

eTASQ Motion carries out functional testing of smartphones, just like a repair centre.

eTASQ Motion

It’s easy to use, no need to know how to code.

Not only will you be able to learn how to use this tool quickly, but it will allow you to test even more devices, thus improving your profitability.

Test reports are generated after each use, ensuring the device’s reliability and traceability before putting it back on the market.

eTASQ Motion, a strong CSR notion, made in France

Created, designed and developed in the Drome region, our testing robot is Made in France.

eTASQ Motion is a facilitator of reconditioned devices. It helps you give a second life to smartphones, thus limiting waste generation related to electronic devices and encouraging the circular economy.

It accompanies you throughout your testing phases, allowing your team to develop their skills and improve their well-being at work (reducing repetitive tasks and musculoskeletal disorders, reducing the feeling of boredom, adding value to their tasks).

Are you also looking to improve your functional tests?